Industrial Release Agents

Industrial confectionary bakeries use release agents to release their baked goods, such as cakes, sponge cakes and muffins, in a flawless and easy manner. Release agents creates a thin film between your batter and your baking materials which enables you to release your baked goods perfectly. Using the right release agent and application method prevents your confectionary products become damaged, contributes to reducing waste and reduces your cost-in-use.

But releasing your confectionary products from tins, moulds, trays or steel belts without any issues can be quite challenging. Your confectionary products may stick to the baking materials and get damaged, the dosing might be too high, the spraying pattern might be wrong, the coatings can get dirty and so on. This can lead to a higher cost-in-use, damaged products, more waste, dirty working environments, a lower lifespan of baking materials and even downtime in production. In this blog, we share the most common issues that we have experienced at production sites of industrial confectionary bakeries worldwide. We will explain you how you can recognise these problems. Do you need advice from our release specialist? Get in touch with them via our contact form.

Release agents

4:23

0:51

1:11

0:47

1:15

1:01

When using release agents in your industrial confectionary bakery, you might run into the following issues:

- Sticky, damaged or dirty confectionary products

- Using the wrong release agent for your baked goods

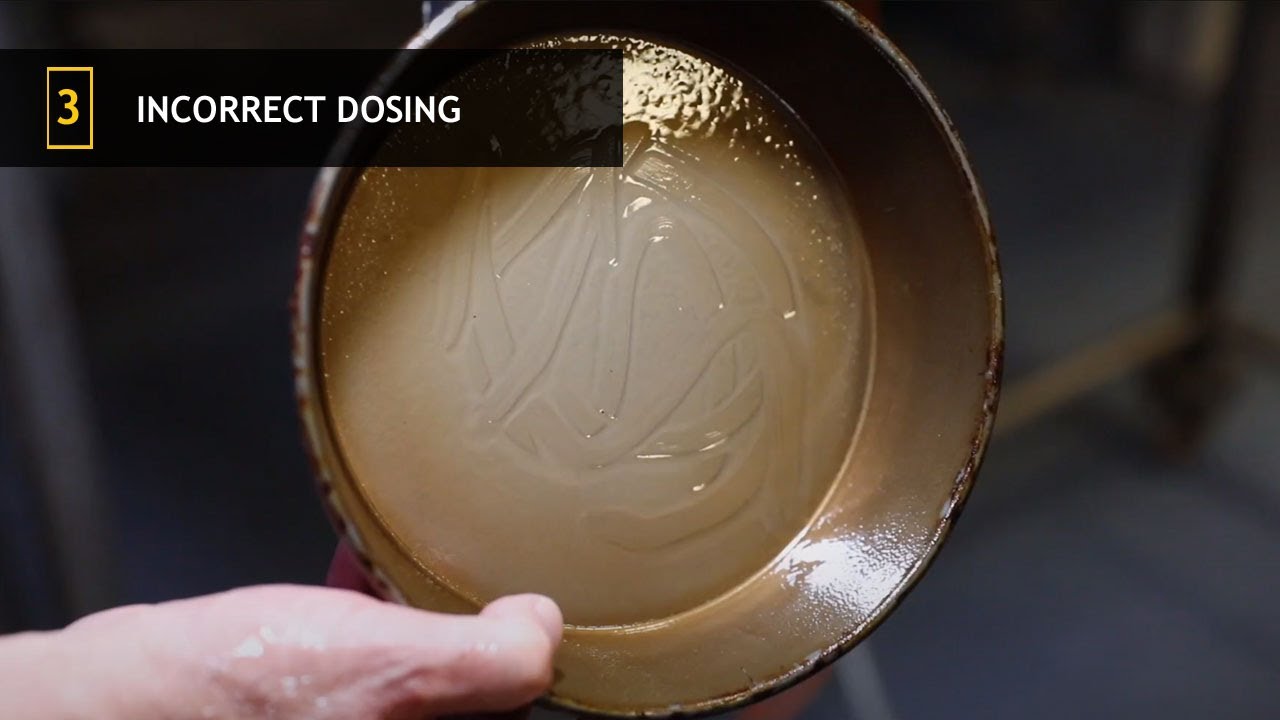

- Incorrect dosing or excessive dosing

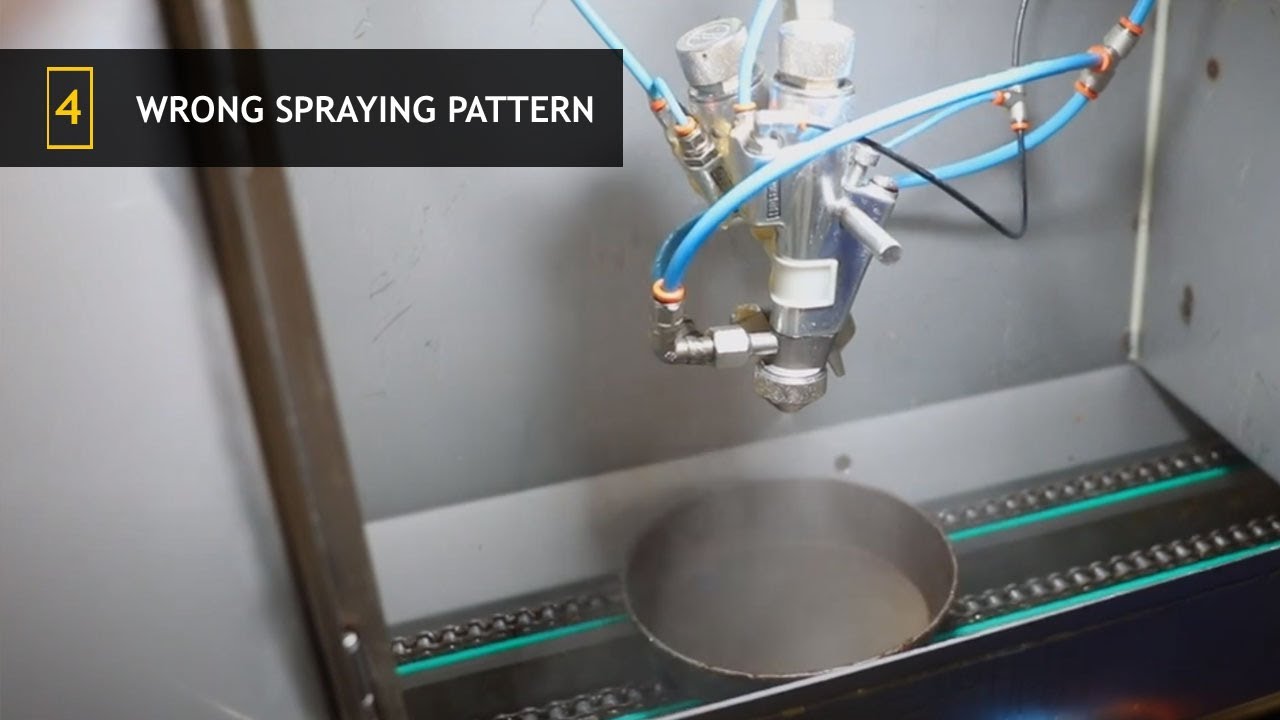

- The spraying pattern of your spraying system is wrong

- Contamination and clogging of filters, hoses and (spray) nozzles

Most of these problems are related to the release agent and spraying system that you are using or the spraying pattern of your (air-mix) machine when the release agent is being applied on your baking materials. Continue reading to find out more about the possible problems that might occur in your bakery or watch the video in which our release agent specialist shares his knowledge about common problems & challenges.